Full Restoration From Start To Finish

Introduction

The restoration we will be following is of a right-hand drive XK140 Drophead coupe. The car was built on the 19th of May 1955 and left the factory on the 2nd of June 1955. It is now red (where the paint is still attached to the body) but we know that it was originally finished in 'Suede Green' with a 'French Grey' hood. The chassis number is 807136, engine number G 3643-8 and the body number is P 3605 all of which match the documents.

We have discovered from some initial research that the car was used for rallying back in the 50s and 60s (see the picture below). As soon as we find any more information about the car's racing history we will update this page. If anyone has any information about the car please get in touch via our contact form here.

The Strip Down

So it's Friday the 13th, unlucky for some but as it happens the lucky number of the owner of the car, and the car has rolled into the workshop. We have begun stripping the car and sorting through the parts. This is a complete car so we will be reusing, refurbishing and restoring as much as possible.

Progress is always quick at this stage of a restoration. This particular car is throwing up lots of interesting surprises already including some of its original paint hidden behind the headlights. So far we have stripped down all the front end, the interior, and the doors and the engine is ready to be lifted out. Thankfully this XK140 has put up very little resistance in the form of stubborn nuts and bolts. As we mentioned before the car is almost complete but what we hadn't appreciated was quite how original the car is. The vast majority of the bolts we are removing are the original "BEES" bolts which are very rare indeed. On removing the dashboard we discovered it still has the body number "3605" written on the reverse; this was used in the factory to identify which car each component was to be fitted to. Other than original bolts, lots of original parts and the odd handwritten number, we are also discovering a lot of corrosion. The chaps at the body shop will really have their work cut out!

RGW 491 continues to come apart nicely. Now that the chrome work, lights and interior are out we can start to assess the extent to which the dreaded worm, tin worm that is, has affected the bodywork. Although the level of corrosion on this car is fairly typical of a restoration project and nothing that cannot be dealt with, we felt it would be useful to put some pictures here to illustrate the extent to which these cars can fall victim to rust.

On removing the exhaust, which as you can see is well beyond repair, a large amount of rust and seeds poured out of the end. There is nothing unusual about an exhaust being filled with rust however the seeds got us scratching our heads. The answer, as it turns out a fairly obvious one, presented itself some hours later when removing the rear bumper irons. As can be seen from the photo, one side of the fuel tank has completely rotted away and a mouse, or several mice, had made their home in there.

The hood has been stripped and removed and the frame is complete. On inspection the frame is in good condition so will be repaired, fitted with new wood and will be reused.

All the trim has been removed from the body and all the mechanical components have been disconnected so the time has come to remove the body. The sills are very rotten so we cut the body in half along the sills to ease removal. First, we lifted off the rear end and then the front end. It looks like the body has never been removed since 1955 so it took four of us to jiggle it free. Then the front end was lifted off over the engine leaving us plenty of room to work around the engine and lift it out.

Now the body is off we can get a good look at the chassis. From the state of the body, we didn't have high hopes for the chassis and we were geared up for extensive repair work. However, this XK140 offered up yet another nice surprise. On inspection, the chassis is in remarkably good condition and should need little more than shot blasting and the odd repair.

With everything exposed the next jobs were to strip down the suspension, remove all the pipe work (fuel lines and brake pipes) and remove the engine. Although this car is remarkably original and hasn't been messed around with too much we did find some inexplicably odd fuel lines running in and out of the fuel pump. Whoever had effected this repair had decided that rather than cutting down the new hoses they were fitting they would leave them long and coil them round each other. On the upside, you probably have an extra litre of capacity in the fuel system as a result. Beyond that the engine came away from the chassis without incident and is now waiting to be rebuilt, the suspension is in good condition and is waiting to be powder-coated and work is already underway on the body.

Bodywork

With the body and chassis separated and stripped, the chassis was sent off to be shot blasted. While waiting for the chassis to come back the extent of the bodywork required could be assessed.

We like to use as much of the original car as possible however most of the XKs we see have had hard lives and once rust has taken hold there is no real choice but to cut it out. Other than a couple of small cracks the bonnet is in good condition under the paintwork and very hard to replace so will be repaired. We will also reuse as much of the door and boot as possible. Usually, we can reuse all the woodwork from the doors and boots but we will repair it if it's rotten and then reskin the doors. We always reuse the wooden door frames because the reproduction alternative is made of steel and doesn't give the correct sound when you shut the door. The rear wings will be repaired but other than that the back end of the car was well beyond repair. Finally, we removed the bottom half of the bulkhead and the bottom of the front wings. This leaves us with the top of the front wings and the top of the bulkhead. Although this may seem drastic it is the only way to get a good as-new finish from the panel work and ensure it lasts. To put this further into context this is the usual amount of work that we will put into the restoration of a body and it's very rare to find a body in any better condition than this. Our experienced team of bodywork specialists will have this car looking better than it did when it first left the factory in no time at all; well a few months!

The chassis has now returned from the shot blasters and a proper assessment of its condition can be undertaken. The chassis has been blasted clean of all corrosion and dirt and then sprayed temporarily to protect the chassis whilst it's repaired. Once all the repair work is done the chassis is then cleaned up again, zinc coated and then painted.

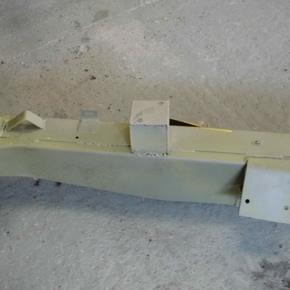

This chassis is in fairly good condition but there are a few areas that will need new metal. The rear leaf spring shackle is a favourite place for rot on XK chassis. The large box section chassis can also allow water to sit inside and rot though when cars are left standing. This was the case with this chassis towards the rear end so work has been started on that. For reasons that have not yet become clear, someone has welded a large, steel block to the right-hand side of the chassis (see above). If anyone has any explanation as to the reason for this block we would be most interested to find out.

Much work has gone into the chassis over the last month or so. Much more new metal was required than was first thought including extensive repairs to the outriggers. We were never able to establish the purpose of the large steel block that had been welded to the chassis so it has been removed. It can be seen amongst a selection of other metal removed from the chassis in the photo. New metal has now been let into the chassis and it is as good as new. All that is left is for it to go off to be zinc-coated and then painted.

Work has now also begun on the body shell. We begin by fitting the bulkhead to a dummy chassis and then fitting the sills. This allows the bulkhead to be aligned to the sills and everything can be built around it ensuring a straight body that fits over the chassis perfectly.

Repair work has also been undertaken on the bonnet and new metal let in. The boot lid has been stripped back to its wooden frame and reskinned, which gives an excellent and strong finish but keeps the original structure, feel and, most importantly, the sound of the boot when it closes.

The doors are also being treated to a new skin. As can be seen in the photos the lower half of the doors were not only rotten but had been inexpertly repaired with a mess of fibreglass, mesh and filler. This has all been peeled off, cut back and removed. What is now left is the original doorframe, which retains that authentic sound when you close the door.

Chassis Buildup

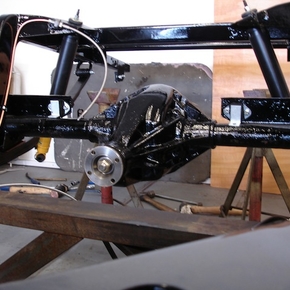

The chassis has now been hot zinc sprayed, primed and painted. Generally, we prefer to paint the chassis rather than powder-coat because paint allows a degree of flex where powder-coating would crack. Whilst the bodywork continues we are now able to start building up the chassis.

This process starts with fitting the rear springs and axle along with the backplates for the brakes; all of which are powder-coated and rebuilt before fitting (no danger of flex and cracking here). The axle for this XK140 has been upgraded to a limited-slip differential (LSD) and a ratio of 3.54:1 which we find works best with our 5-speed gearbox conversion. The car is also retaining its original drum brakes on the rear because we find discs are not necessary on the rear an XK and the handbrakes are very poor on the XK disc brake setup.

Next, we start to build up the front suspension. All the parts are checked for damage, then powder-coated and fitted using polyurethane bushes. This combined with an uprated 22mm anti-roll bar, Spax fully adjustable shock absorbers and our own tried and tested suspension geometry (developed through racing) greatly improves both ride and handling over the original car.

For modern and enthusiastic driving front disc brakes are a must. We use Jaguar XK150 front discs with modern four-piston aluminium brake callipers and a servo. This setup is a great improvement over the standard drum brakes on an XK120 or XK140 and is even a worthwhile upgrade on an XK150.

The chassis build-up continues with the fitment of an aluminium fuel tank which is more resistant to the corrosive effects of modern fuels, the wiring loom being run through the chassis and as much of the pipe-work as possible. This XK is also having twin solid-state Facet fuel pumps fitted which are much more reliable than the old points style pumps. Next, the wiring, which runs through the chassis from front to back for the fuel sender and fuel pumps, is fitted and then we are ready to complete the chassis by installing the engine and gearbox.

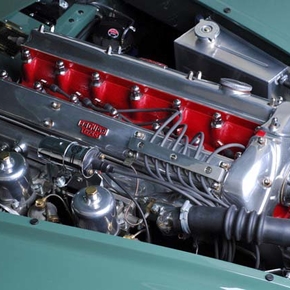

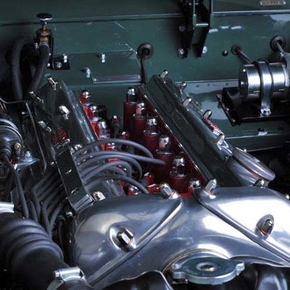

This engine, which has been built in-house, is a "fast road" specification. This means it has a pair of upgraded Newman cams, 9:1 aluminium pistons with total seal rings, gas flowed cylinder head and larger inlet valves. All components are also balanced to give the smoothest running engine possible. We build engines to any specification required so please get in touch for more details.

The engine and 5-speed gearbox are put together before being lowered onto the chassis along with a modern diaphragm clutch (giving a much lighter clutch pedal than the original spring clutch) and a hi-torque starter motor. We then fit the uprated aluminium radiator and the chassis is now built and ready for the body to be lowered over the top. Building the car this way around saves a lot of time and avoids the risk of damaging the body during the buildup stage.

This chassis was then out and about at various shows and it has proved to be very popular. We have displayed it alongside one of our finished restorations and it provides a real insight into how good these cars look under the body.

Putting it back together

When it comes to restoring a Jaguar XK it is not just a simple case of "putting it back together" as Jaguar built them in the 1950s. We expect more today from these cars and here at Twyford Moors, we aim to deliver. Shut lines must be as close to perfect as possible and lines down wings must be flawless. Originally these cars were only painted where you could see, we ensure every inch of our restorations are painted to the highest standard and where panels meet each other they are protected by waxoyle.

As with the preparation and finish of the chassis, everything we do to the body is focused on the twin aims of an excellent finish and long-term protection. Testament to this was an XK140 drophead coupe which we had in for sale recently. The car had covered over 90,000 miles since our full nut and bolt restoration 20 years previously but for a slightly used-looking interior and some stone chips, the car is still in top condition. These cars are built to last.

Whilst the chassis has been trailered to shows all over the country drawing admiring glances, work has continued in the background on the body. The body has been completed on a slave chassis which is the best way to get the shape exactly right. Before it is painted much time is taken to fit up all the components to ensure all holes are where they should be and the right size. It's very easy to fettle, drill and do any other necessary work to get everything fitting perfectly before paint. Once we are happy everything fits then all is stripped again and it's off for paint.

When it comes to the bodywork on these cars it is as much art as it is engineering and never more so than the paint finish. Our restorations are all painted to the highest standards using modern two-pack paints. The finish is excellent and it does not matter where you look on the car, under the wings, behind the dashboard or in the boot, the finish is top-notch.

At this point one must make what is probably the single biggest decision of the restoration process; paint colour! Sometimes this is very simple, if you are all about originality the car must be its original colour, but if not the choice is yours. We can paint an XK in almost any colour the owner chooses which can often make it very hard indeed. We have even been asked to paint a car to match the colour of the owner's helicopter.

After some research (and finding some original paint behind the headlights) it was discovered this XK140 was originally Suede green with a Suede green interior and a French grey hood. The decision had already been made not to keep the red that the car had been repainted but should it be returned to its original colours? Much deliberation went on, and two major worries kept coming up; would green on green be too much and for some years now French grey mohair for the hoods has been near impossible to get hold of. If we went for the Suede green paint and interior without the French grey hood as a contrast it might just be too much. Eventually, the decision was taken to go with the original colour scheme and after an extensive hunt, the closest possible material was found for the hood.

When it rolled out of the paint shop this XK140 divided opinion. Some loved it and some were not convinced (including the owner). Without any chrome or hood, this is a very green car but will it come to life as we put it together?

Now the car has been painted it is time to reunite it with its chassis and get stuck into the reassembling process. The first step is to lift the body off of the slave chassis which we have been using to build and paint the body.

Our favoured technique is to roll the body on the slave chassis onto our two post ramp, fit strengtheners to the body, clamp it onto the ramp arms and then unbolt the body from the chassis. We can then use the ramp to lift the body away and minimise any unwanted movements twisting or flexing the body. We then simply push the slave chassis out of the way and roll the freshly restored chassis, engine and all, in under the body and lower it back down. Using skates under each wheel of the chassis allows fine adjustments to be made and we can get the body onto the chassis very quickly indeed and minimise the risk of anything moving.

Fit up

Now that the body and chassis are reunited we can get cracking on the "finishing touches". Although the XK looks almost finished at this point there is still much work to be done, much of it very precise and it is certainly these final stages of the process which make the difference between a good restoration and a stunning restoration. This is also the point at which our specialist knowledge really comes into its own. As XK specialists we know all the ins and outs of how these cars go together, where the wiring should be routed, how the hood wood should be fitted and so on. They say the devil is in the detail and that is certainly true here. Without this level of experience, you can put the car back together in such a way that it will function but it will not be correct.

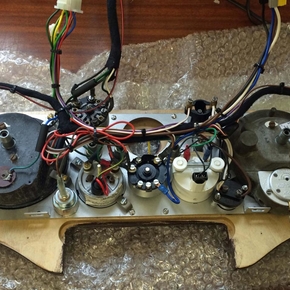

This process takes time and started way back before the body was painted. Everything has been pre-fitted so should fit without too much fuss but there is always a little bit of fettling to do. All our chrome work is undertaken by a specialist company who do truly wonderful work and they are even capable of getting a good finish on Mazak. We start with fitting powder-coated parts such as bumper irons and headlight bowls. The wiring harness is run in at the same time as this as the two processes need to be done side by side to ensure everything can be reached. The wiring harness is modified to our specification before being fitted to accommodate the various upgrades which will be fitted to the car.

One of the most significant jobs on these cars is fitting the woodwork. It is not a simple case of buying the wood and fitting it. All XKs are slightly different and the wood must be trial fitted and made to fit the unique shape of each car. This is especially important when it comes to the hood wood. This must be fitted and then shaped by hand to perfectly follow the contour of the top of the screen and the rear bulkhead. If this is not done properly the hood will not seal and might not even close properly. A poorly fitting hood will always leak.

The process continues with bumpers, lights (once the wiring is in), door handles, rubbers and glass. The list goes on and on when you get to this point but it is all about care and attention.

The electrics

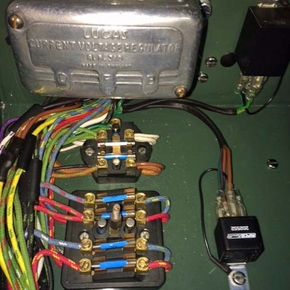

All our restorations are built to the customer's exact specifications. This can be anything from completely standard to extensively modified for modern driving. More often than not customers opt for many upgrades and this is most apparent in the electrical system. This XK140 is having electronic power steering, an electric cooling fan, an uprated wiper motor and a hidden stereo system amongst other upgrades. All these upgrades put additional demands on the electrical system making an alternator essential to keep up with the power demands. The wiring loom is also modified extensively to accommodate all these upgrades in a neat and efficient manner. An additional fuse board is also fitted to the car, hidden inside the now-disused regulator box, for all of these upgrades.

Other electrical upgrades on this car include halogen lights, additional rear indicators, footwell lights, a third brake light housed in the reverse light and a volt meter in place of the ammeter. Although the ammeter can be upgraded to cope with the higher output of an alternator and demands of power steering etc we favour using a voltmeter as it gives useful information to the driver.

Mechanical work and fluids

The XK has now been fitted up and wired up. Everything has been tested and is working so it is time to put in fluids and get the car running. All the pipework that was already fitted to the chassis is connected up to the reservoirs which are fitted to the body, the radiator is fitted and the cooling system is complete and the pedals have been carefully fitted to give the best driving experience.

The brake and clutch system are filled with modern silicone fluid and bled out, coolant is filled up and tested, the five-speed gearbox has been filled and 20w50 oil is ready to lubricate the rebuilt 3.4-litre XK engine. The time has come to fire the car up for the first time in decades.

Although starting a rebuilt engine for the first time is a nervous and very exciting time, especially in a long-term restoration where the car has been off the road for decades, it is rarely eventful. In the case of this XK with electronic ignition, a high torque starter and lovely 2" SU carburettors the engine fired almost immediately. The engine is timed up and tuned to run nicely and now the car can move under its own power. It will need to be run with care for the first 1000 miles before it can go for a rolling road tune-up and we can see what this car is capable of.

Now all the oily jobs have been done the car can be cleaned and then trimmed.

Trimming

The woodwork has all been trial fitted, shaped and veneered ready to go back on and the hood wood is ready for the hood to be trimmed. Before the carpets go in we fit Dynamat throughout the interior, particularly to the bulkhead and gearbox tunnel. Dynamat is truly wonderful stuff which reduces not just noise but also vibrations and heat in the car. It is however fiendishly difficult stuff to fit nicely. It is sticky-backed and once it is on it is on! We follow a very carefully made set of templates to ensure that it fits the contours of the interior perfectly to not cause issues when fitting carpets or seats and to keep noise and heat out.

The trim chosen for this car is Suede green as per the original with a French grey hood. The early concern over the colour combination is now a thing of the past; the finished result is truly stunning.

After the trim is fitted, the veneered woodwork can be refitted, including the specially manufactured Moto-Lita steering wheel which is a special darker shade to match XK dashboards.

The final task and one which takes a huge amount of skill, care and patience is fitting the hood chromes. These must be shaped by hand to fit the hood, then carefully removed, sent to be chromed and then refitted without damaging the chrome. It is always a real transformation when the hood chromes are fitted. It separates the hood from the body, highlights all the lines and really brings the car to life. If you have ever seen an XK drophead without the hood chromes fitted you will know exactly what I mean.

The finished product

So there you have it. A Twyford Moors full nut and bolt restoration from start to finish. We are truly proud of this car, as we are of all our restorations, and it has received a lot of positive attention. You may well have seen it at the London Classic Car Show, NEC Classic Car Show or the Goodwood Revival. It has also been featured on the cover of Classic Jaguar Magazine and XK Gazette and featured in the Netflix series "The Crown".

If you are interested in a full restoration and would like more information please click here to get in touch with us.

The Finished Specification

Original UK, right-hand drive Jaguar XK140 Drophead Coupe with matching number in its original colour scheme.

-Fast Road 3.4 Engine

-2" SU Carburettors

-Twin Solid State Fuel Pumps

-Electronic Ignition

-Electronic Power Steering

-Alternator

-Five Speed Gearbox

-Limited Slip Differential

-Front Disc Brakes

-Aluminium Four Pot Brake Calipers

-Brake Servo

-6J Chrome Wire Wheel with Radial Tyres

-Electric Cooling Fan

-Aluminium Radiator

-Header Tank

-Upgraded Wiper System

-E-Type Electric Screen Washer System

-Foot Well Lighting

-Hidden Stereo System

-Inertia Seat Belts

-Wood Rim Steering Wheel

-Additional Brake Lights

-Additional Rear Indicators

-Twin Spot Lamps