A Full House – Workshop Update

As you can see from this photo, our storage space has filled up now that autumn has arrived. The workshop is abuzz with both servicing and restoration work on everything from early XKs to V12 E-Types and more. We have some really exciting projects to share with you in this update and over the coming months, so do stay tuned for those.

The NEC Classic Motor Show is just around the corner, running from the 8th to the 10th of November. This is always a most enjoyable weekend, so it’s well worth a visit. We will be in our usual spot in Hall 2, Stand 550, near Iconic Auctions. We’ll have some beautiful cars on display, and the team will be on hand to chat about all things classic Jaguar. So, please do come and say hello if you’re visiting.

In this workshop update, we feature emergency brake repairs, an unusual XK engine upgrade, chassis repairs, 3D printing, beautiful stainless steel exhaust manifolds, and more. So, grab a cup of tea, or something stronger depending on the time of day, and have a peek at what we’ve been up to in the workshop.

Jaguar Fixedhead Coupes

Although convertibles are the most popular models we care for and sell, we believe Jaguar has produced some exceptionally attractive fixedhead coupes over the years. Pictured here are two of our favourite hardtops.

On the right is an XK120 fixedhead coupe. Introduced in 1951, the FHC was a redesign of the original XK120 roadster, but the results are stunning. One could be forgiven for thinking that the original design was intended to be a hardtop. There are hints of the earlier SS100 coupe prototype in the design, along with a good deal of the Bugatti Atlantic. The XK120 FHC is a beautiful and very practical classic, although not ideal for taller drivers or those who struggle with flexibility. However, we can overcome many of these issues by fitting an extended pedal box, bucket seats, and power steering with a smaller steering wheel.

Over the next decade, Jaguar produced some stunning coupes, with the XK150 FHC being a personal favourite, but it must be acknowledged that the E-Type coupe was a game changer. Ten years on from the stunning XK120 fixedhead, which must have looked so modern at the time, the E-Type feels like another leap forward. So, the only question is: which one would you like to take home?

Jaguar Enthusiasts’ Club Visit

Last week, we were delighted to host the West Sussex and Hampshire Jaguar Enthusiasts’ Club for a workshop tour. Thanks to everyone who visited and brought along a wonderfully diverse variety of Jaguars, both old and new, to fill our car park. Upon arrival, we all enjoyed a cup of tea, cake, and a chat. We then had a tour of the workshop, highlighting some of the more unusual projects and rarer cars. Finally, our visitors had time to chat with our team, ask any questions and share stories.

One question that came up multiple times was whether we would be willing to work on more modern Jaguars, such as 1990s and 2000s XJs and XKs. We are best known for our work on 1950s XKs. Over the years, we have worked on more E-Types and have become one of the few specialists who excel in working on V12 E-Types. Beyond this, we care for many classic saloons, pre-war SS cars, and the odd XJS. We don’t generally work on anything more modern than that—not because we can’t, but because the workshop is fully booked as it is. However, it is clear to us that there is a need for a specialist to look after these more modern Jaguars, which the main dealer network is no longer interested in, and we will continue to consider this.

Jaguar XK140 Touring

Pictured here is Reggie, the Twyford Moors XK140 drophead coupe, which was restored and upgraded in 2016. Back in September, Nik and Hazel took the car to Angoulême for the Circuit des Remparts with our friends at Classic Travelling. The team at Classic Travelling organise some wonderful tours, both within the UK and abroad. The focus is on enjoyable and relaxing motoring trips, taking in beautiful locations, fun driving roads, and comfortable hotels. These are social and fun tours, allowing you to get out and use your classic car as intended.

The Circuit des Remparts tour was no exception, with some wonderful driving roads in France before enjoying the racing in the historic city of Angoulême, with its iconic cathedral. Good food, company, and hotels along the way made the whole journey a pleasure. We have some exciting plans with Classic Travelling for next year so watch this space for more details.

As for the XK140, it performed perfectly. The five-speed gearbox makes it an easy car for covering motorway miles, and the disc brakes and electric power steering make city driving a breeze. The electric cooling fan, alternator, electronic ignition, and solid-state fuel pump make this a very reliable and dependable car. Inside, inertia seat belts, USB charging sockets, and a hidden radio make the car a comfortable place to be. If you are considering touring, please contact us to discuss suitable upgrades.

Jaguar MKII Performance Upgrades

Pictured here is the front suspension of a Jaguar MKII saloon in the process of being upgraded. Earlier in the year, we built a fast road 4.2-litre engine coupled to a five-speed gearbox for this car. The owner's vision is to create a seriously fast resto-mod car with performance well beyond that of the original, while still looking fairly standard. The engine was in need of a rebuild, so that was the first job, but we are now setting about a series of supporting modifications so that the rest of the car can keep up with the additional power.

The suspension has been fully rebuilt with polyurethane bushes. The shock absorbers have been upgraded with adjustable gas shocks, and the anti-roll bar has been upgraded. The mismatched tyres have been replaced with a good quality set of Blockley tyres, which we consider to be one of the most important parts—after all, they are the only part of the car that touches the road. With the car now able to go around corners properly, we are turning our attention to the brakes. In the photo, you can see a new aluminium calliper carrier has already been fitted. This will take a four-pot aluminium brake calliper, which, combined with vented brake discs and fast road brake pads, will significantly improve stopping power. It is important when upgrading a classic to consider all aspects of the car to ensure it is safe to drive.

Jaguar C-Type Replica

We just couldn’t resist getting a photo of this lovely C-Type in the morning sun. It is a Realm kit with a fibreglass body. It looks great, is fun to drive, and all at a fraction of the cost of the real thing. We’ve done a lot of work on this car over the past twelve months for the owner. Like many home-built replicas, the parts were sound, but the build process left a little to be desired. Many of the suspension bolts had come loose after some use due to either not being sufficiently tightened originally or not being properly secured in place.

When the owner first brought the car in with handling issues and wheels rubbing against the body, we thought it might just be a damper issue, but it turned out to be the rear suspension moving under load. We rebuilt the front and rear suspension, upgraded it with polyurethane bushes and adjustable shock absorbers, and ensured everything was properly secured. This process was transformative, and our customer then enjoyed a summer of track days in the car. Towards the end of the summer, the car developed a charging fault, and as we had already identified that the alternator conversion and bracketry left something to be desired, the car is back with us for electrical improvements and a better quality alternator conversion.

XK Block Heater

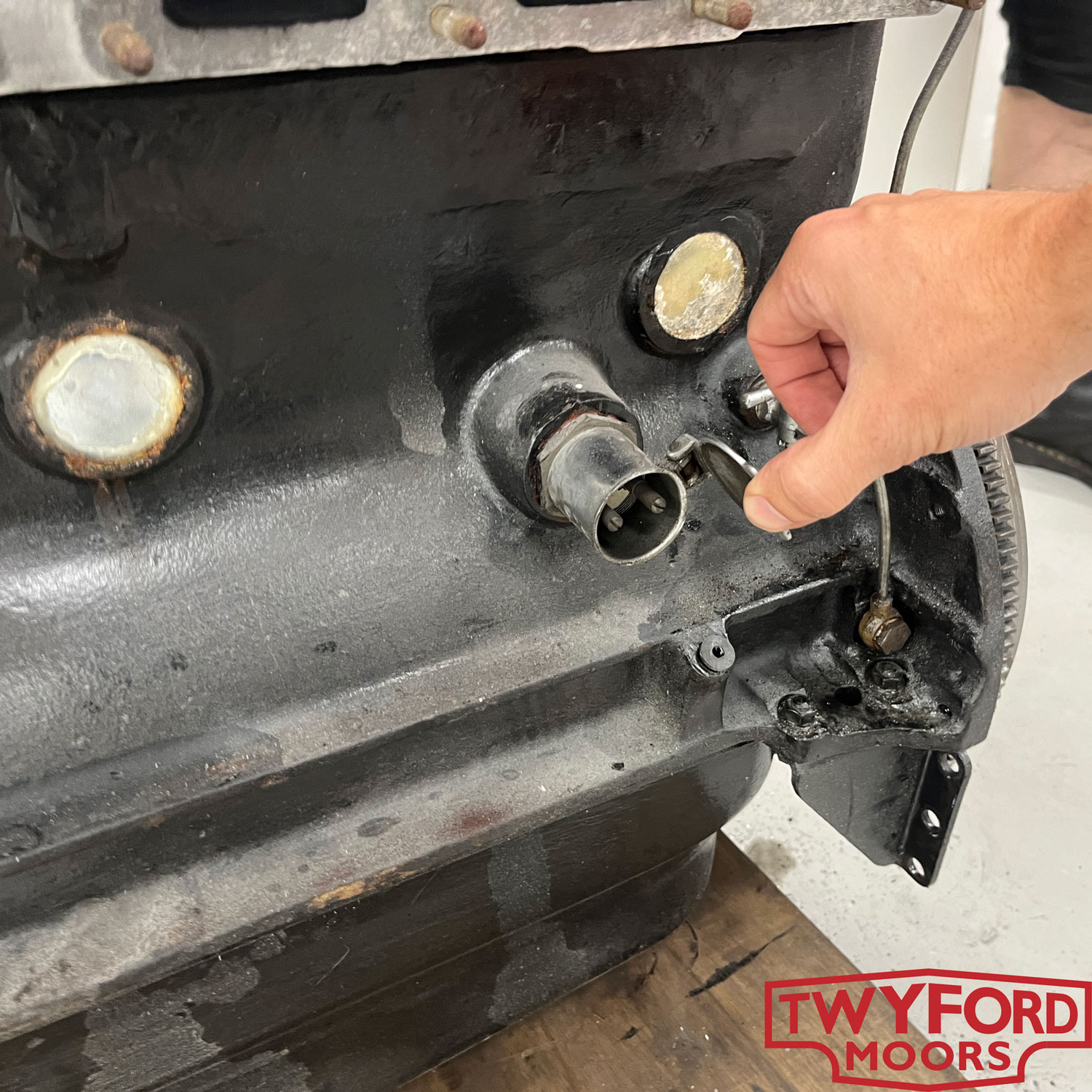

Here’s something you don’t see every day, and if you do, you might not know what it is. This slightly abstract photo shows an XK engine block on the exhaust side, between the rear two core plugs. To the right of the photo, you can just make out the teeth on the flywheel, and at the top, you can see the exhaust manifold studs. In the middle of the photo, you’ll see a socket, not dissimilar to a modern 16-amp socket, which goes into the block. This is an original block heater, which is a rare thing to see, at least here in the UK.

These block heaters were most commonly fitted to North American and Scandinavian cars—essentially anywhere that gets really cold. I’m not sure if they were fitted as standard for export to these locations or if they were an option. They go straight into the waterway and have a heating element on the other side. You would presumably have had a lead to plug into your mains supply at home, allowing you to preheat your coolant before starting the car. I have never seen one in use, and I wouldn’t recommend using one even if you did have the correct adaptors, but it is an interesting thing nonetheless. If anyone has more information on these, I’d love to hear it.

Jaguar E-Type Engine Removal

This Jaguar E-Type has come in for a new clutch. Although I have heard many people claim to have changed an E-Type clutch without removing the engine, I have yet to see it done. I suspect it must involve a lot of modification to the bodyshell to do so. In reality, if you know what you are doing and have the proper facilities, removing the engine and gearbox from an E-Type isn’t as big a job as it might seem and is certainly the best way to do the job.

With the engine out, we will be checking everything over, refreshing core plugs where necessary, and attending to any other items requiring work. Once the engine and gearbox were out, the owner decided this was a good opportunity to upgrade to a five-speed gearbox. We often hear from E-Type owners wishing they had an extra gear to make the car a bit more suitable for motorway driving. Our five-speed gearbox upgrade leaves the gear selector in its original location, allowing the car to maintain its original appearance whilst benefiting from improved shifting and a fifth gear. The owner has also asked us to fit the car with a new six-branch stainless steel exhaust manifold and stainless steel exhaust system. We will try to get some photos of this as we progress.

Jaguar XK140 Automatic Gearbox Conversion

Sometimes, when restoring or upgrading a car, you come up against unique challenges. In the case of an XK140 drophead coupe, which is currently undergoing a full restoration, the gear linkage has proved to be an interesting conundrum. The owner wanted us to fit one of our upgraded automatic gearboxes, which is no problem at all, but he wanted to retain the original XK140 column gear selector. This is something we have never done before.

With the rather tricky linkage now working, we are looking at the final piece of the puzzle. As the order of the gears on the new gearbox is not the same as on the original and they are spaced differently, we need to recreate the plastic cowl that goes on the gear selector. Our very clever friend at Chalkpit Design has 3D scanned the original, and pictured here is a 3D-printed prototype just to check for fit. There is still more work to do here, but the first prototype was a perfect fit, so now we just need to work on the labelling and the finish of the cowling. We will share more updates, and hopefully a video about this process, in the future.

Jaguar XK120 Emergency Repairs

One morning back in September, I arrived at the workshop to find an E-Type and this XK120 parked out front. Not expecting anyone to drop off their car that day, let alone at 7:50 am, I was a little confused. Going over to speak to the owners, it turned out that they were from France and their ferry had landed in the UK earlier that morning. They were on the first day of a classic car tour, driving thousands of miles across the UK. En route to the ferry in France, the XK120 had developed a very unpleasant noise when braking. Being active members of the classic Jaguar community, they knew of Twyford Moors and drove the car straight here.

We were able to quickly get the car onto a ramp in the workshop and provide the waiting drivers and passengers with a nice cup of coffee and a warm place to sit while we inspected the car. We quickly found that the noise was caused by the front brake pads being worn down to the metal. Fortunately, we had the correct parts in stock, and with a bit of work and a short test drive to ensure all was well, we were able to send our European friends on their way to enjoy their tour.

Chassis Corrosion

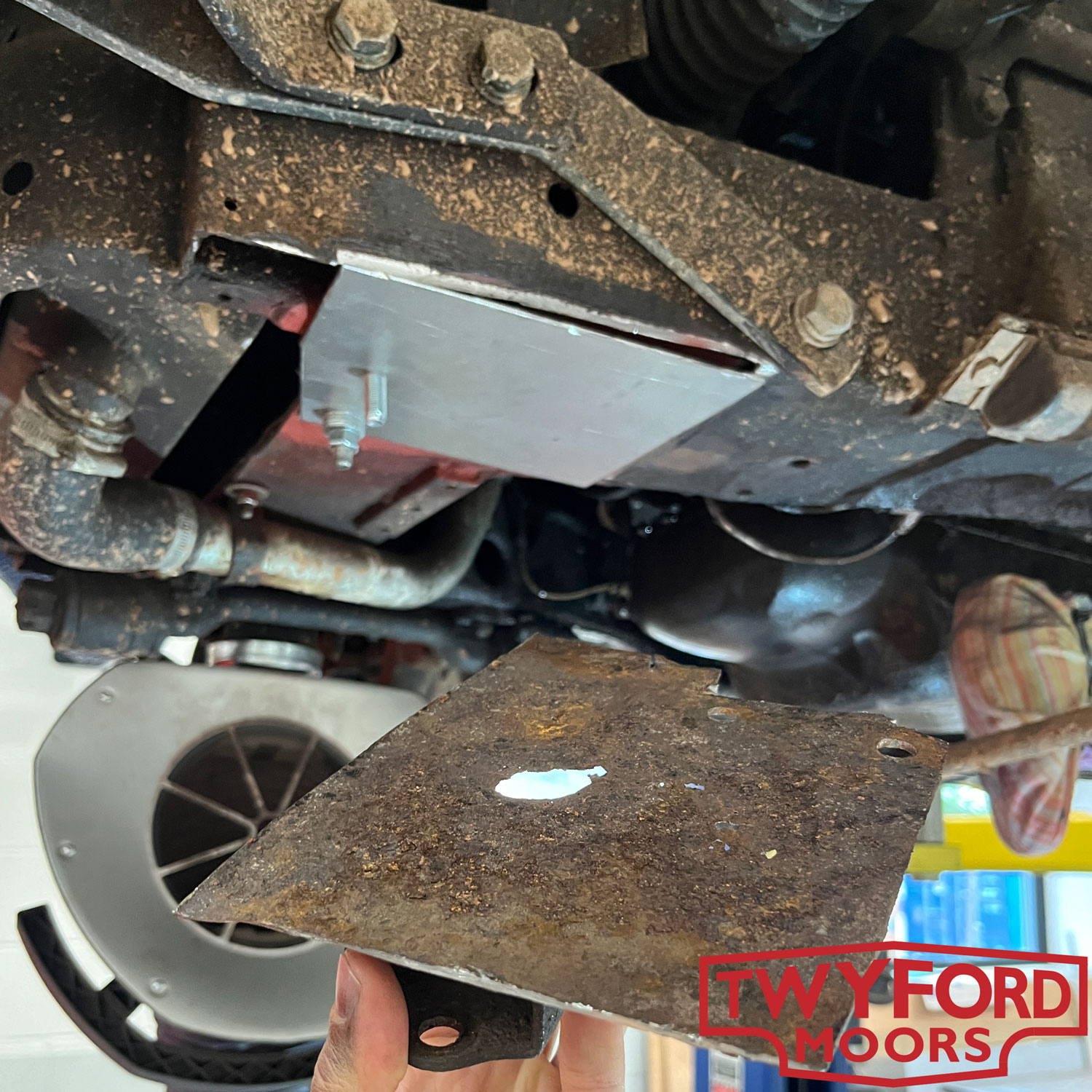

XKs are generally pretty robust cars and not any more prone to rust than any other car of their vintage. It’s worth remembering, though, that almost all classics will have gone through a period of their life when they were worth very little and may not have been well-maintained during this time. There are some common places where XKs do suffer from corrosion, and a favourite is where the front wishbones and anti-roll bar bolt onto the chassis. We always check this area and are well-practised at repairing it, so do not fear if you have a bit of corrosion here.

In the foreground, you can see the section that has been cut out from the chassis. It was very thin, which clearly is not ideal, given that a lot of force goes through this area. You can see a 50p-sized hole just in front of the anti-roll bar mount, and there were a number of pinholes that are harder to see.

In the background, the first section of new metal to be welded in can be seen. This will be tacked into place and then seam-welded to maximise strength. It is not uncommon to see smaller, localised repairs or patches put over the top of this kind of thing on cars that were ‘restored’ decades ago, but this is far from best practice.

Jaguar E-Type Series 3 Exhaust System

We see a lot of V12 E-Types these days. It seems we are fast becoming the go-to specialist for them, as we have the skills and parts to make them into the fantastic machines they should be.

This E-Type has come in for a significant mechanical refresh. The owner brought the car to us to check over and provide recommendations on how to improve it. We have carried out much mechanical work, such as replacing worn suspension bushes, rebuilding the carburettors, and removing a troublesome old immobiliser system. At the same time, the owner asked us to convert the car from steel to wire wheels and wanted a new stainless steel exhaust system.

The system we are fitting here is a full stainless system from our friends at Classic Fabs. These systems look stunning, sound great, and are very well-designed and built. Pictured here is one of the beautifully made exhaust manifolds, which I wanted to get a photo of, as once it is installed in the car, it will be pretty well hidden away. Although it is not as highly polished as the rest of the system, you have to admire the craftsmanship that has gone into something you can hardly see.

Jaguar XK140 Show Chassis

This chassis belongs to an XK140 drophead coupe. This particular car is rather special in that it was used by Jaguar Cars as a show car in 1955. The car was the 40th right-hand drive XK140 to be built, and as a special equipment car, it had all the bells and whistles. The heritage certificate even lists the car as “Jaguar Cars Ltd – Show.”

We are currently building this chassis up to showcase our restoration work and upgrades. This chassis will be on display at shows over the coming twelve months, and we hope to have it at the NEC Classic Motor Show in a few weeks’ time. Among other upgrades, the chassis will be displaying our five-speed gearbox upgrade, electric power steering (which you will be able to test), disc brakes, and upgraded suspension. The car will be rolling on a lovely set of wheels and tyres provided by our friends at Blockley, and there will be a stunning stainless steel exhaust system from Classic Fabs. Keep an eye out for future posts featuring all these lovely parts.

This XK has a fantastic history and is being built to an incredible specification. It is available to buy and can be finished here at Twyford Moors to the buyer's specification.

Jaguar XK140 Valve Clearances

The XK engine is famed for its groundbreaking design and performance. The twin overhead cam system was well ahead of its time in 1948 and provided performance and efficiency that other manufacturers couldn’t dream of. However, the system comes with its own set of challenges. I’m sure many of our readers will have tinkered with engines on cars ‘back in the day’ and will perhaps have set the valve clearances on an A-Series engine or similar at some point. To do so, you whip off the rocker cover, crack out a set of feeler gauges and some spanners, and adjust away.

The nature of the twin overhead cam system on the XK engine makes the process a little more complex, with measurements having to be taken before the camshaft is removed to allow access to change shims underneath. Fortunately, our team is well-practised at this task and knows exactly how to get your XK running as smoothly as a sewing machine.

If your XK engine has a bit of a rattle, there are a number of things it could be, from timing chains to tappets. Please get in touch if you think your engine needs a bit of a health check.