Embracing Jaguar's History – Workshop Update

It has been an interesting time to be a Jaguar enthusiast in recent weeks. If you’re unsure what I am referring to, take a moment to watch Jaguar’s recent advert. Combined with the news that they will not be selling any cars in 2025, many are worried about Jaguar’s future. I’ve heard it suggested that Jaguar’s old slogan, “Grace, Space, and Pace”, should be changed to “Waste, Haste, and No Taste”. Personally, I remain hopeful for the future of the brand and genuinely want them to succeed. If nothing else, Jaguar has succeeded in getting people talking about the brand, which hasn’t happened for a while. If they can back this up by releasing stylish and well-built cars in 2026, they might just pull off an epic comeback.

In the meantime, we’ll carry on embracing Jaguar’s extraordinary and pioneering history by maintaining and championing the wonderful cars that helped shape the brand we know and love.

In this update, we’re featuring a full house of restorations, including an XK120, XK140, XK150, and an E-Type. We also take a closer look at diaphragm clutch upgrades, E-Type handbrake upgrades, and a truly shocking shock absorber.

Jaguar XK120 Fixed Head Coupe Restoration

Here we have a Jaguar XK120 Fixed Head Coupe (FHC), on which we are currently carrying out a full nut-and-bolt restoration. I’ve said it before, and I’ll say it again: the XK120 FHC is, in my opinion, one of the most attractive cars ever produced. In this deep British Racing Green, it looks stunning, and once the chrome work is fitted, the contrast will really highlight the car’s lines.

The body has just returned from being painted, has been lowered onto the chassis, and is now in the process of being built up. We prefer to fully assemble the chassis with suspension, brakes, fuel and brake lines, engine, and gearbox before fitting the body. This method is far more efficient than working around the body and minimises the risk of accidental damage. We also try to prepare as many parts as possible off the car while the bodywork is being done. For example, the vast majority of the electrical equipment has already been refurbished and prepared, so our electrician can get straight on with running the wiring and fitting the parts. The engine and gearbox have already been tested on our engine test rig, so we know they’re ready to go.

We’re building this car to a very specific specification for the owner, who wishes to use it for touring and rallies. If you’d like to discuss having a car restored to your dream specification, please get in touch.

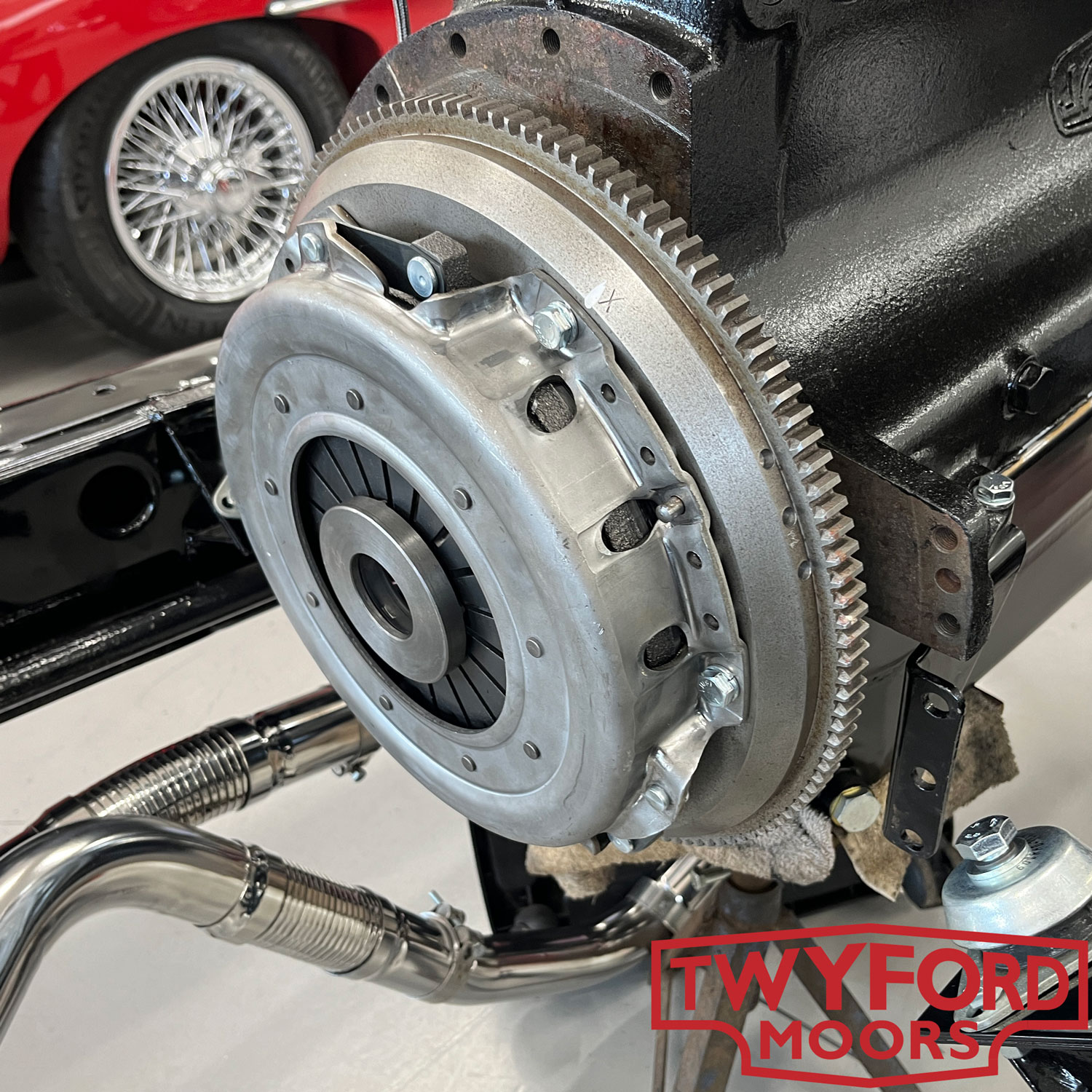

Diaphragm Clutch Upgrade

Pictured here is a modern-style diaphragm clutch mounted to a lightened and balanced flywheel. When we undertake a clutch change for a customer, we fit a lightened, skimmed, and balanced flywheel as a matter of course. The flywheel is balanced with the clutch cover fitted to ensure the pair are perfectly aligned, providing the smoothest power delivery possible.

The most significant change and advantage here, however, is the diaphragm clutch. Compared to a spring clutch, a diaphragm clutch requires less pedal effort and provides a smoother clutch feel, making your classic car easier and more enjoyable to drive. A diaphragm clutch also applies uniform pressure across the friction plate, self-adjusts for wear, offers higher clamping force, and has fewer moving parts. All these advantages combine to create a stronger clutch that will last longer.

As many of you will know, a clutch change in an XK or E-Type is an engine-out job. As such, we are keen to ensure that the interval between clutch changes is as long as possible for you.

Jaguar E-Type Five-Speed Gearbox

We featured this 3.8 Series 1 E-Type a few weeks ago when the engine was removed for some work. The car is now fully reassembled and being prepared for the owner to collect.

Over the past few weeks, we have undertaken an extensive programme of improvements to this car. Most notably, we have fitted a five-speed gearbox. Our five-speed gearbox conversion is proving to be very popular for both XKs and E-Types. In fact, we are also seeing increasing demand for these gearboxes in MKI and MKII saloons. A five-speed gearbox significantly enhances the usability of these classics in modern driving conditions. It allows for quicker gear changes and makes motorway cruising a much more relaxed experience.

All our five-speed gearbox upgrades are designed to preserve the car's original appearance as much as possible. The gearstick remains in the same position, and we offer a variety of gear knob options to suit your taste. When the original gear knob is fitted, the only way to tell the car has a five-speed gearbox is by looking underneath it.

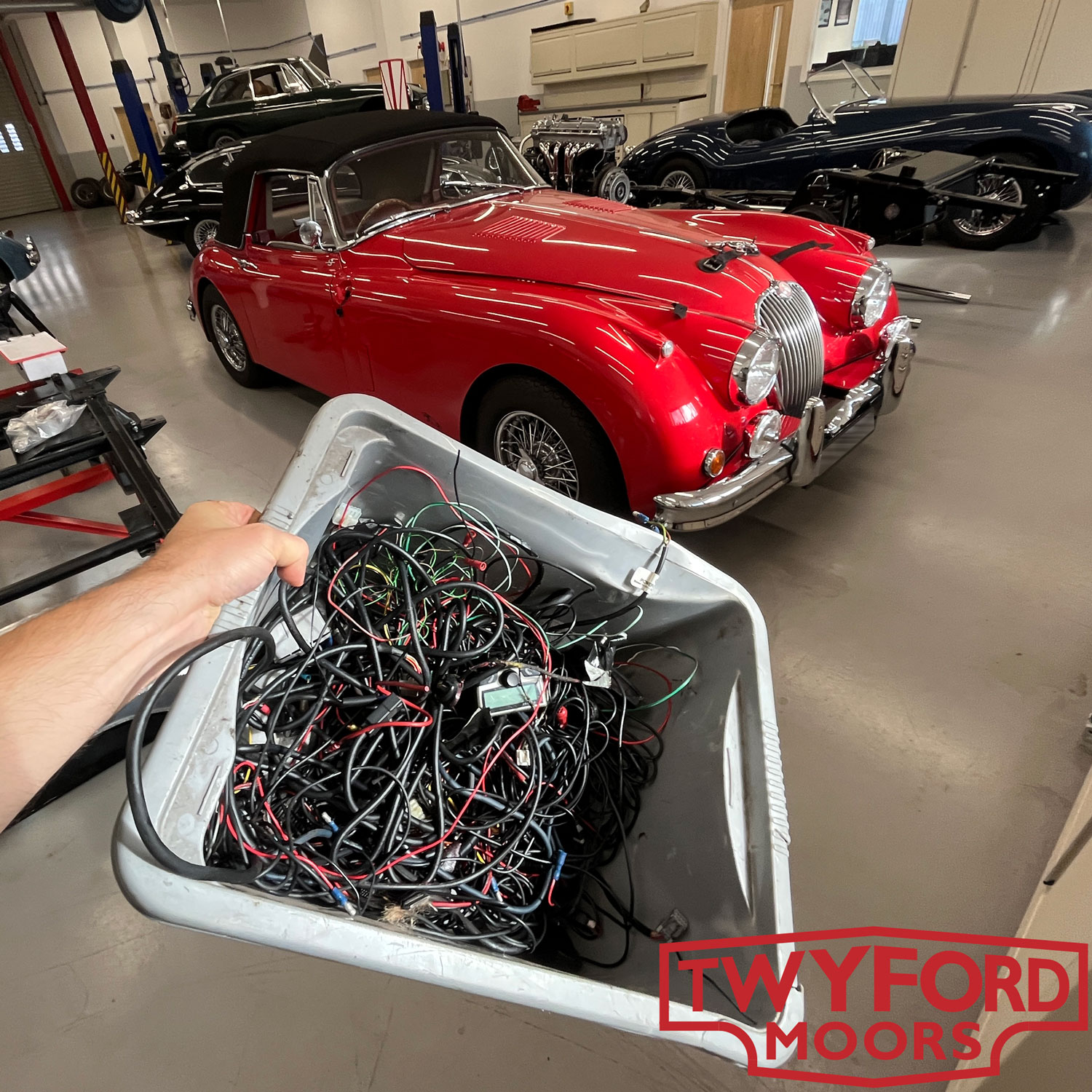

Excess Wiring

Classic car wiring isn’t a glamorous topic. Few of us want to spend money on the wiring in our classic car, as it won’t make it go faster, handle better, or even look any different—unless the wiring is a real mess. However, poorly maintained, modified, or ageing wiring is the cause of a disproportionate number of breakdowns.

We frequently see cars still retaining their original wiring. Over the years, this wiring has often been pushed out of the way and exposed to solvents and paint during repairs. Combined with age, this leaves you with wiring that is brittle, prone to failure, and difficult to work with due to faded colour coding.

In addition to these issues, we often find cars with an abundance of extra wiring. This is particularly common in vehicles restored during the 1990s and 2000s. Such additions are often made for accessories like electric cooling fans, radios, alarms, immobilisers, or even reversing sensors. Unfortunately, these modifications are often poorly executed, leading to reliability issues, unsightly wiring, and difficulty in servicing the car.

The XK150 pictured here is a perfect example. The car had extensive extra wiring installed, much of which was poorly fitted and caused numerous problems. The box in the foreground is filled with excess wiring that we removed from the car, along with several redundant systems.

European Visitor

A significant proportion of the cars we work on come from all over the world. We have customers as far afield as Hong Kong, North America, Australia, and South Africa. Although we saw a decline in visits from our European neighbours immediately after the Brexit vote in 2016—and this continued as the UK left the EU—we are pleased to report a return of our European customer base.

As the new relationship between the UK and the EU has begun to settle and the arrangements have become clearer, we are now able to bring cars in and out of Europe with confidence. While it isn’t as straightforward as it once was, at least we now understand the process.

This lovely Jaguar XK140 DHC has come to us from Germany. We first met the car’s owner at the Goodwood Revival, where we assisted with a minor electrical fault in the car park. The car is now with us for a full check-over, a service, the fitting of a brake servo, and some bodywork repairs.

We are delighted to see more of our European friends feeling confident enough to bring their cars to the UK for work once again. We hope to continue strengthening our bonds across the Channel.

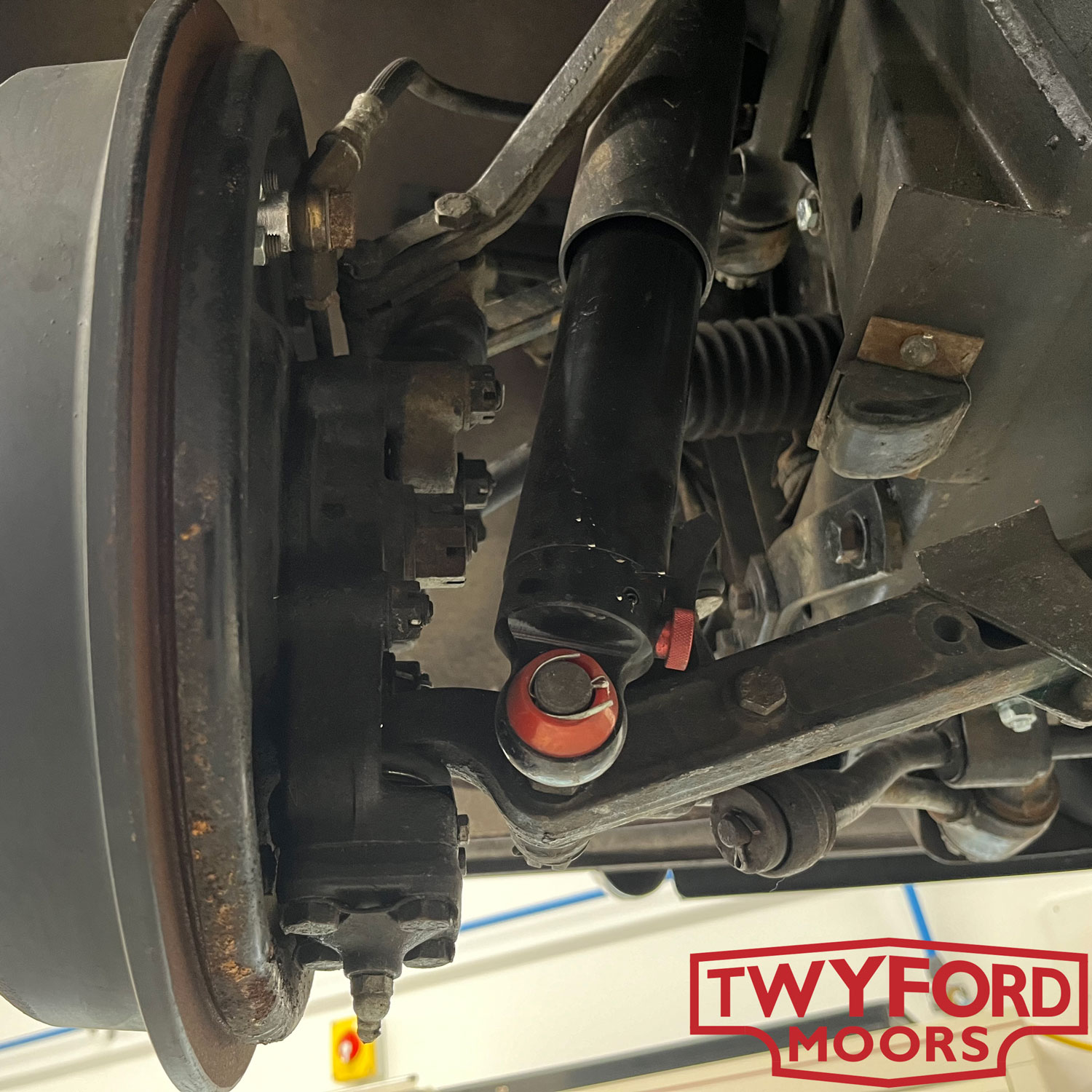

Shocking Shock Absorber Mounting

Over the years, we have worked on countless classic cars—some good, some bad, some plain ugly. Occasionally, however, we encounter something that truly stops us in our tracks. This was one of those “just when you think you’ve seen it all” moments.

The image shows the front suspension of an XK140 that recently came to us with a clutch fault. The owner also asked us to check over the car and provide a report, which is a common request. We are always happy to inspect cars and provide owners with a detailed report. From there, we can carry out further work if desired, or the report can be used to guide future decisions. However, in this case, one issue was so safety-critical that action needed to be taken immediately before the car was driven again.

If you haven’t already spotted it, the offending item is the lower shock absorber mount (the bright red bush). The washer that should secure the bush in place hasn’t been fitted, and the split pin used is far too small. The result is that the front shock absorbers are being held in place only by the weight of the car and the head of the split pin pressing against the bush.

Jaguar E-Type Restoration

We’ve been sharing updates on this E-Type restoration as progress continues. The fabrication process on this car is nearly complete. The shell is now fully reassembled and solid once more. It will shortly be dipped again and then submerged in a protective coating that will prevent corrosion for decades to come. After that, the car will be ready for paint.

Before the car leaves our fabrication workshop, a few final jobs remain. We’ll make the necessary modifications to fit the five-speed gearbox and ensure everything fits properly, such as the window mechanisms and rear quarterlights. It’s worth taking the extra time at this stage to ensure everything is correct, rather than discovering the need for alterations after the paintwork is completed.

Meanwhile, significant work has been progressing elsewhere to prepare other components. The engine has been rebuilt and mated to the gearbox, ready for installation. The rear axle and subframe have been rebuilt and upgraded with adjustable shock absorbers, uprated brakes, and polyurethane suspension bushes. Additionally, the electrical and trim components have been overhauled.

Jaguar XK140 Drophead Coupe Restoration

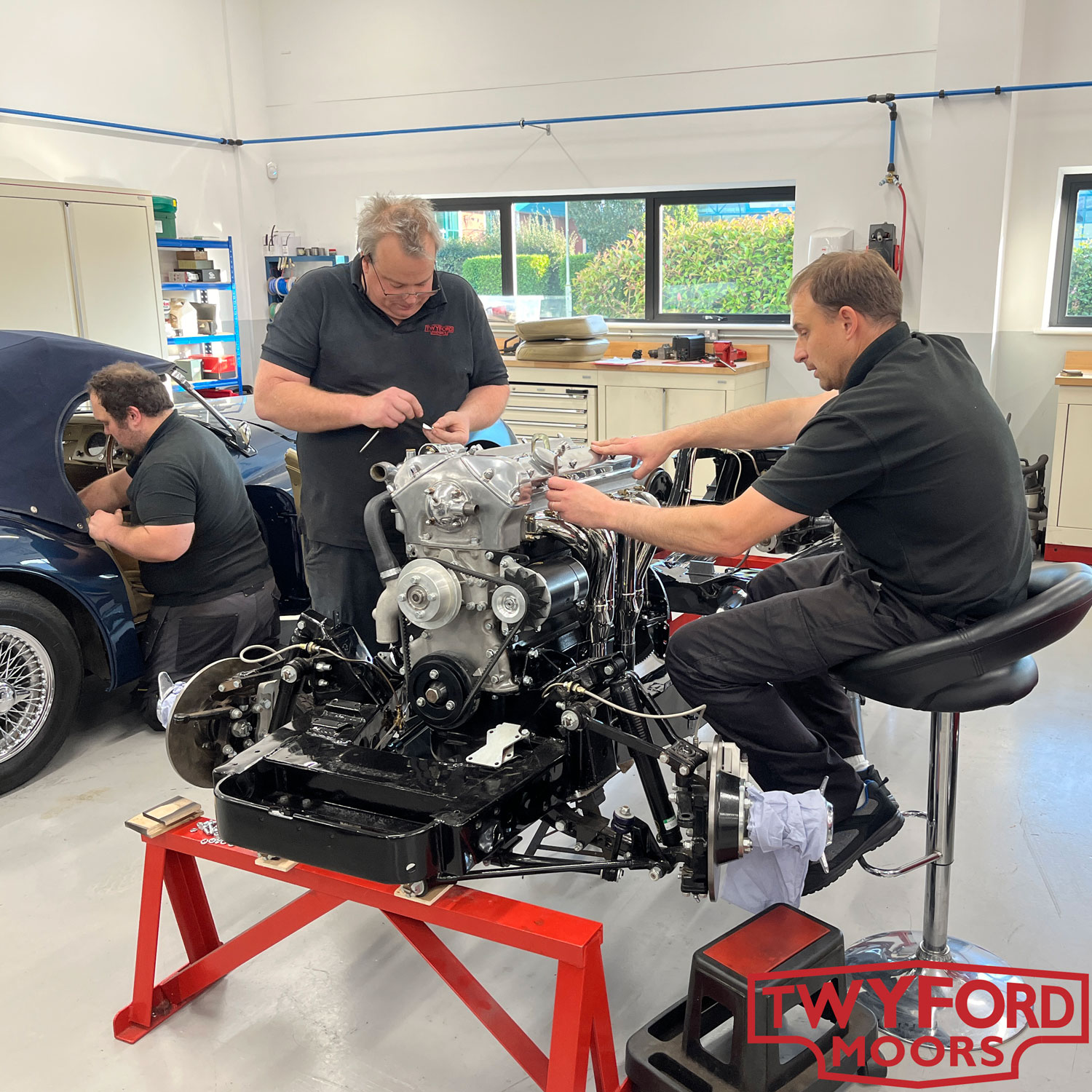

Ahead of the NEC Classic Motor Show a few weeks ago, our team pulled out all the stops to get this Jaguar XK140 DHC chassis ready for the event. Particular thanks go to Martin, pictured here sitting on a stool while fitting the stunning exhaust system from Classic Fabs. Martin manages our workshop, ensuring everyone knows their tasks and that cars are finished on time. It was a big ask to fit this project into an already packed schedule, but he made it happen, delivering the chassis just in time.

What’s more, the reason Martin is sitting on a stool is that he was recovering from a knee operation at the time but hardly let it slow him down.

A big thank you also goes to the rest of our team, who worked tirelessly to bring this project together in time for the show. Darren, our engine builder, is pictured here fitting a freshly rebuilt set of carburettors after completing the engine rebuild and installation into the chassis.

This chassis attracted a lot of attention at the NEC and became a major talking point. It was an excellent way for us to showcase the quality of the work that goes into the underpinnings of our restorations and to demonstrate many of our upgrades.

Jaguar XK150 3.8 S Restoration

This Jaguar XK150 3.8 S is an extremely rare original UK right-hand drive drophead coupe. Over the years, I have heard various claims as to how many of these were built, but it was certainly fewer than fifty and perhaps as few as eighteen. Interestingly, we recently had three in the workshop at the same time, and we still have two here now.

Many consider the 3.8 S to be the ultimate expression of the XK range. The larger 3.8-litre XK straight-six engine, equipped with a straight port head and triple 2” carburettors, was the power unit that later drove the E-Type but first proved its mettle in the XK150 S models. These rare and sought-after cars have a distinct character compared to standard XK150s.

Although a standard XK150 with a 3.4-litre engine is a powerful and enjoyable car to drive—capable of keeping up with modern traffic—the S models take performance to the next level. When driven gently, they feel similar to the standard car, but when you put your foot down, the additional power becomes undeniably apparent.

Jaguar E-Type Series 3 Exhaust System

Pictured here is the underside of a Series 3 (V12) E-Type. We have been carrying out an extensive refresh for the owner, which has included significant work on the suspension, brakes, and carburettors. The owner also sought our recommendation for an exhaust system, and we had no hesitation in suggesting a Classic Fabs system.

As the photo shows, these stainless steel systems are true works of art. The meticulous design and engineering behind them make them not only visually stunning but also the best performance option available for road cars. They maximise the potential of the V12 engine, enhancing both gas flow and exhaust sound.

While these systems are slightly more expensive than some alternatives, their exceptional design and fit often save on labour costs during installation. These systems are also available for straight-six E-Types and XKs and can be fitted to standard manifolds or paired with stainless tubular manifolds. Classic Fabs even offers an option to include catalytic converters.

Jaguar XK150 Fixedhead Coupe Restoration

I’ve always had a soft spot for the XK150 FHC. Its fixed-head design perfectly complements the proportions of the XK150, resulting in a car that resembles a sportier version of the MKII saloon. These models combine performance and practicality in a way I find very appealing, and they represent excellent value for money compared to equivalent convertibles.

This particular car hasn’t been in our workshop for a couple of years. The owner has been restoring it at home for some time, and we’ve assisted with aspects of the work he wasn’t confident undertaking himself.

Now that the car has been largely assembled, it’s back with us for a thorough check and finishing touches. We will ensure everything has been done correctly and safely. The owner has also provided us with a list of tasks he struggled with or found problematic, and we will work through those issues. Once we’ve completed our work, the car will be ready for trimming.

We’re always happy to help fellow enthusiasts with their projects. If any aspect of a restoration feels too daunting for your skillset, please don’t hesitate to get in touch. From rewires to engine rebuilds, we’re here to assist with home restorations.

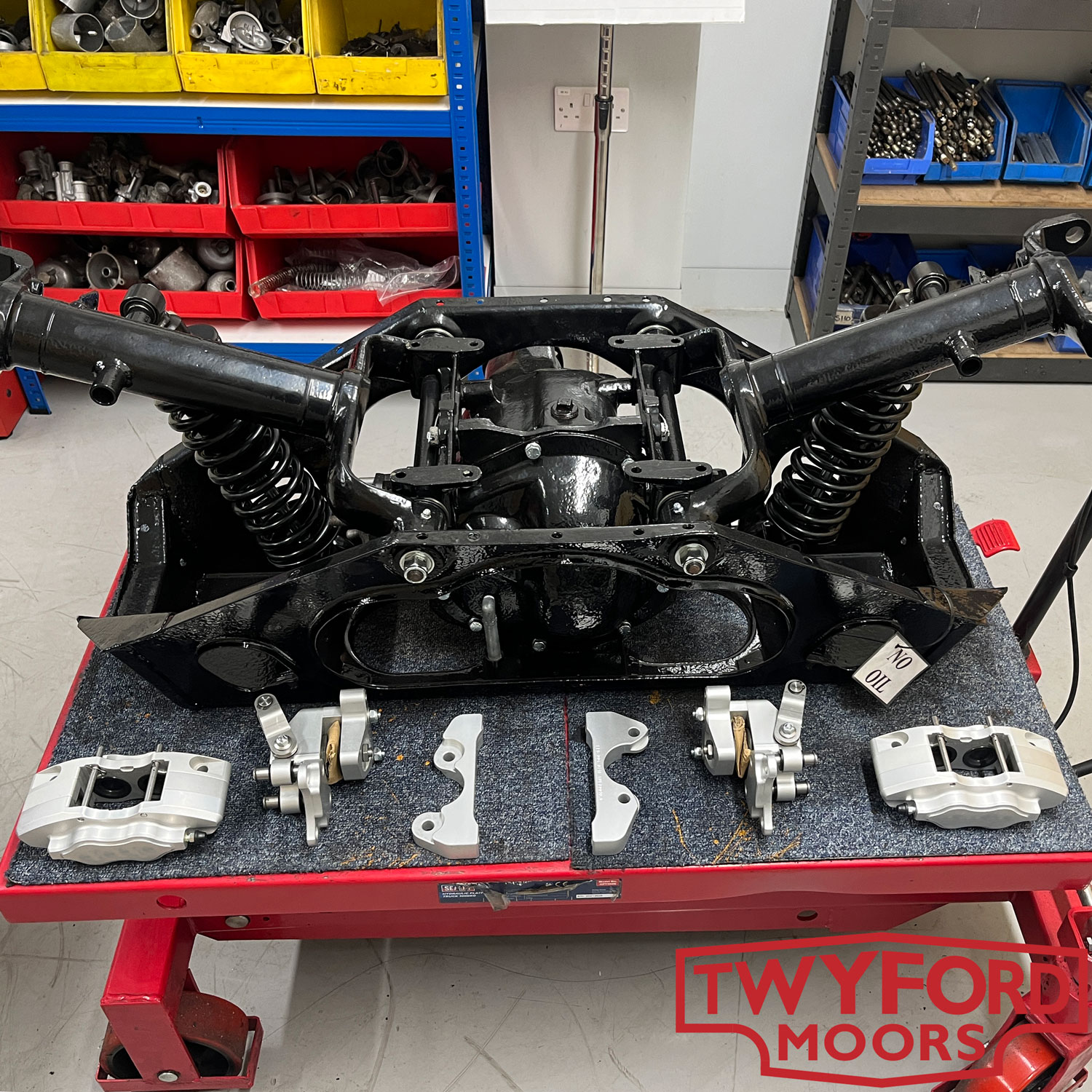

Jaguar E-Type Rear Brake Upgrade

This slightly abstract photo shows a Jaguar E-Type rear subframe turned upside down on our hydraulic trolley. The entire assembly has been stripped, cleaned, and powder-coated, while the differential has been rebuilt. The next step is to fit the brakes before installing the drive shafts.

When working on E-Type rear axles, it’s often best to remove the entire subframe. Although this involves some extra labour, the time saved by having easy access to all components usually offsets the additional effort.

Anyone familiar with living with an E-Type, XK150, or MKII saloon will know that Jaguar’s early disc brake system, while excellent on the foot brake, has a significant flaw: the handbrake mechanism. The handbrake on these models is not particularly effective and requires regular adjustment to function well. On E-Types, this task is made even more challenging by the inboard brakes, making an upgrade to the rear brakes a worthwhile consideration.