Looking forward to an exciting 2024 – workshop update

We are back at it after a well-earned Christmas break. We hope you all had a wonderful festive season and wish you all the best for 2024. Last year was a big year for us moving into our new workshop, hosting and attending some fantastic events and working on some fascinating projects. As we approach our first anniversary in our new building we are pleased to say we are thoroughly settled in and up and running smoothly. Just ahead of Christmas, we made a few final adjustments to make the building work perfectly for us. Now that we have settled in and got used to our new place of work we are pleased to be looking to recruit another mechanic and potentially more staff as the year goes on to meet our now expanded capacity and increasing demand.

In this update, we will look back at the final event we attended in 2023, check in with some restorations, pop into our clean workshop to see some engine and axle work and even take a peek at a MK V drophead coupe.

Motoring Literary and Art Festival 2023

Last month we were fortunate to take part in the inaugural Motoring Literary and Art Festival. Taking place in The Wing at Silverstone it was a wonderful show to close out the motoring year and fills a niche which until now has been rather overlooked. This event brought together the great and the good from across the motoring world. There were book signings, discussion panels and some really fascinating theatre sessions. A highlight for us was hearing Lord Hesketh speak about Hesketh Racing, James Hunt, racing in the 1970s and F1. He certainly didn’t hold back! Alongside the theatre events, there was an impressive shopping area with automotive books, art and memorabilia. Everything the motoring enthusiast could want.

On the ground floor in the pit garages was the ‘Star Cars’ part of the show with a truly breath-taking array of cars ranging from ‘Old Number 8’ (the SS100 pictured here) and the Ferrari Breadvan. There was also the oldest E-Type in existence, ‘The Italian Job E-Type’ and the XK120 which belonged to Sir Stirling Moss. To watch a short film of the full line up of classic Jaguars we had on display please click here.

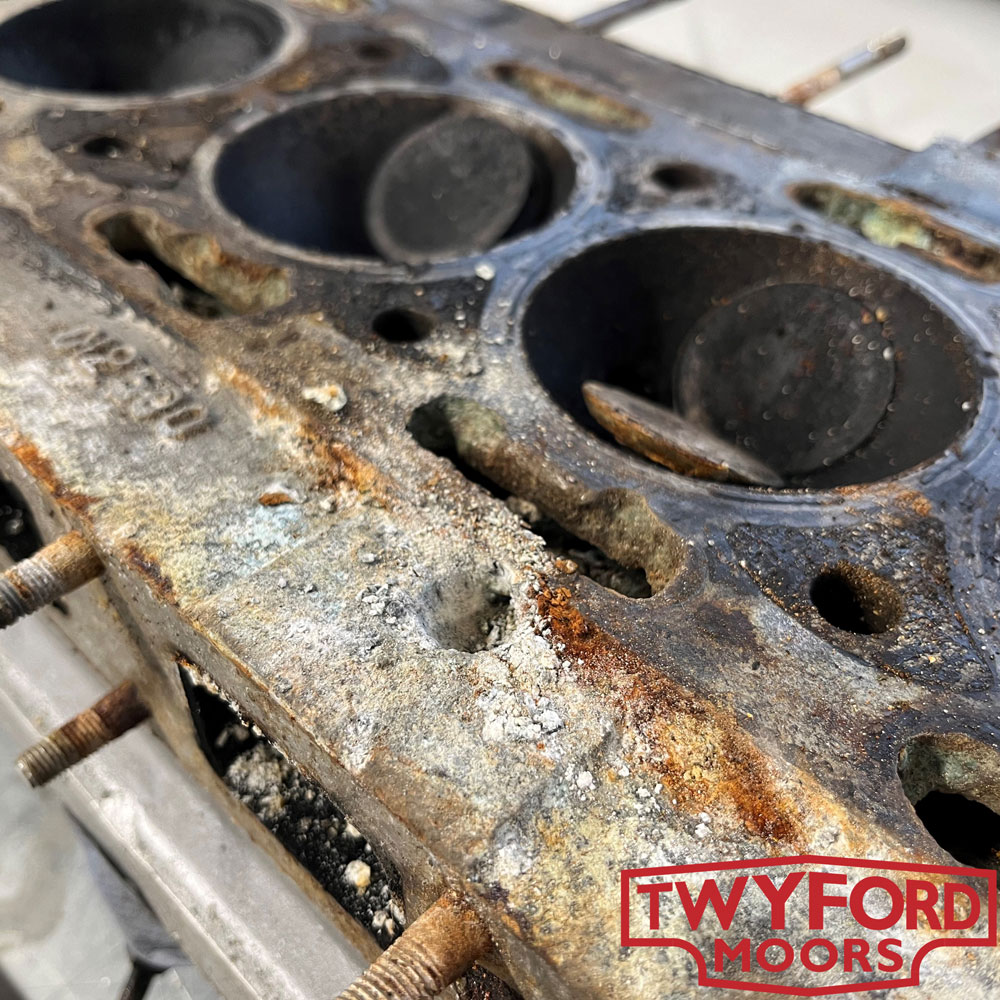

Corroded Cylinder Head

XK engines are incredibly robust, well-designed and, for their time, powerful engines. They do though require proper maintenance to remain in good condition. This ranges from the relatively complex like keeping the carburettors tuned and the timing right to the very basic such as checking fluids. It is not only vital to check your fluids and top them up as required but also to ensure that they are changed at appropriate intervals and that the correct products are used. Antifreeze not only acts to alter the freezing and boiling point of water but it also inhibits corrosion in the cooling system. XK engines are particularly susceptible to this due to the combination of an iron block and an aluminium cylinder head.

Pictured here is a close-up of the cylinder head which came off an XK120 suffering with excessive water leaks. As can be seen, the waterways have been corroded away and there is a hole in the cylinder head outside of the head gasket area. One suspects this is the result of years of neglect and insufficient maintenance. Although with modern technology we can carry out some quite remarkable repairs to cylinder heads and engine blocks we fear this one may be too far gone with damage inside the waterways.

Aluminium Jaguar XK120

We could not resist sharing this shot of our fully restored Aluminium Jaguar XK120 OTS. It had just been through the workshop for its winter check-up and was out for an after-dark test drive and just looked stunning all lit up. This car is a very early XK120 manufactured from aluminium over an ash frame before Jaguar moved to steel production. Charmingly it is chassis number 120.

Some of you may have seen the car out and about over the past few years. It was used at the Goodwood Revival a few years ago in the Freddie March Spirit of Aviation enclosure to be displayed next to a DC3 aircraft. Goodwood went on to borrow the car to create some of their marketing material for the Revival so whenever you see an XK120 in one of the Revival adverts it is probably this one. More recently we had the car on display at the Motoring Literary and Art Festival. Who knows what adventures are in store for it in 2024 but watch this space because you’re sure to see this very special XK120 again soon.

Jaguar E-Type restoration

In our last workshop update, we shared a photo of this Jaguar E-Type right at the beginning of being stripped down for restoration. It is an early 3.8 litre Series 1 Coupe which the owner has asked us to fully restore and build him the car of his dreams. It is an honour to be trusted with such a project and to have to opportunity to create the car someone has longed for since childhood.

As you will see from the photo the car has now been completely stripped back to the body tub. We are very pleased with the condition of the shell and are confident that there is little rust in it. Despite this in order to carry out a restoration to the very highest standards the body must go back to bare metal and inside ever section of the car needs to be inspected, repaired and treated to prevent future corrosion. With the car now complete stripped, the shell and subframes will have all the oil paint and filler removed before being coated in a rust protector. This process involves submerging the car so that every surface inside and out is treated and bonded to the rust protector electrically.

Jaguar XK150 storm damage

The XK150 pictured here has come to us to have some damaged trim and paint repaired. During a recent storm, an oak tree fell and went through the roof and wall of the garage where this XK150 was kept. All things considered, the car got away lightly. The tree and the main body of the debris missed the car and there is no significant panel damage. Unfortunately, there is not a single panel on the car which has not been scratched or chipped and there was quite a lot of damage to the car's interior as well.

This is one of the more unusual accident repair jobs we have been involved in. We are no stranger to dealing with damaged classic cars. Unsurprisingly most of this sort of work is crash damage and usually involves minor bumps and scrapes. The vast majority of these bumps and scrapes seem to occur in car parks, garages or generally at low speeds.

Over the years we have built up a great deal of experience working with insurance companies to ensure your repair goes smoothly and is stress-free for both the insured and the insurer. If your classic’s body work is in need of some tlc or you have a little bump or scape this year please do get in touch.

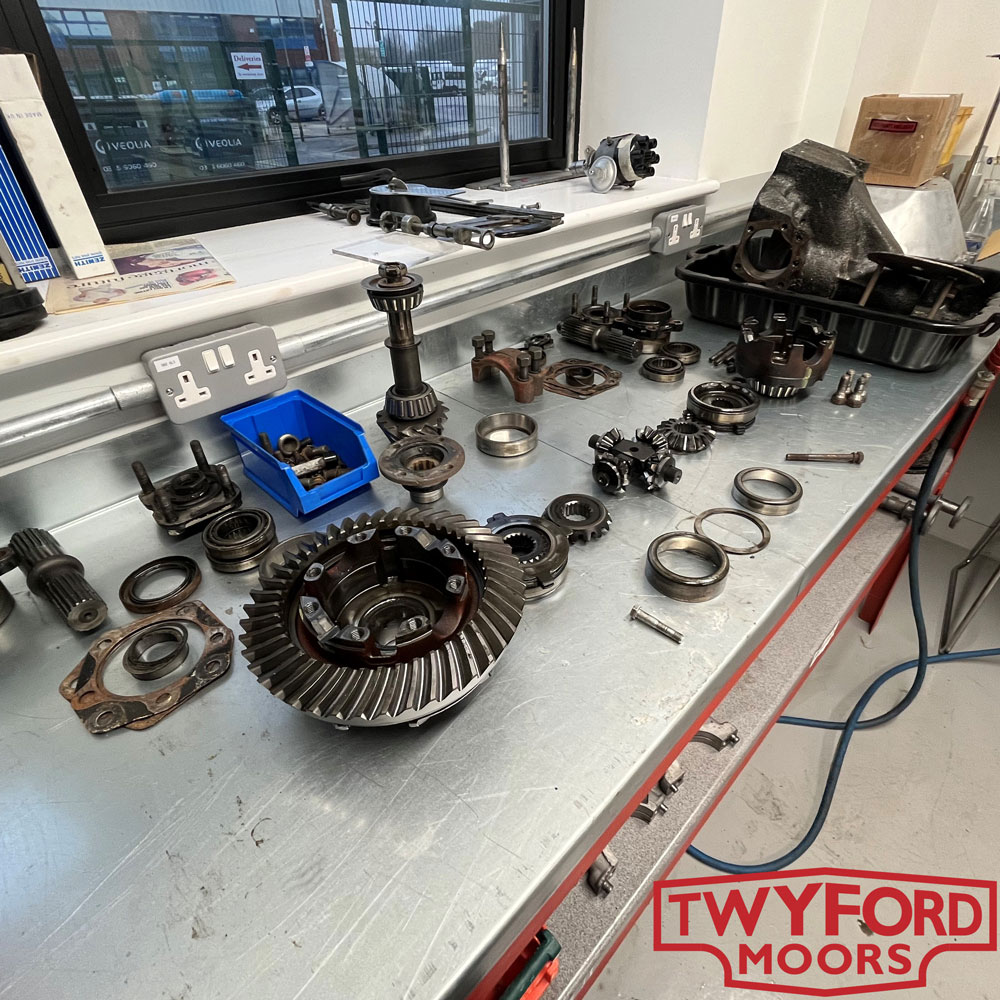

Jaguar E-Type differential rebuild

Pictured here is a Jaguar E-Type differential stripped down for rebuild. As you can see, when we undertake this kind of rebuild, we strip the units back to their component parts. Everything is then cleaned and thoroughly inspected. Any damaged or worn parts can be replaced at this point. We can rebuild axles and differentials for all sorts for classic cars. The XKs mostly had Salisbury axles fitted for which most parts are available however some crown wheel ratios can be hard to come by. The early XK120s had ENV axles fitted which are extremely challenging to get parts for. These ENV axles were also fitted to pre-war SS Cars such as the SS100.

We are able to undertake this kind of rebuilds both for in-house projects and for those working on their cars at home. If you are restoring a car and need help along the way please do not hesitate to get in touch. Be it a differential rebuild, full engine rebuild or carburettor overhaul we would be happy to help.

Jaguar E-Type show car

As many of you will know our ethos is to build cars to be used. We focus on providing practicality and reliability within a stunningly restored car. With the addition of sensible upgrades XKs and E-Types can be enormously enjoyable and reliable to drive whilst retaining their classic character and look. More than this, modern build standards, paintwork and rust protection allow us to build cars which can withstand the elements much better than they did in period. If you haven’t watched our “Built to be driven” video on YouTube please do take a moment to watch it. It shows us getting out in our fully restored XK140 and using it whatever the weather.

All that being said we look after quite a number of stunning concourse and show cars. Sometimes it can really take your breath away how immaculately these cars are kept by their owners. Pictured here is the underside of a Series 2 E-Type which is just such a car. It was restored some years ago and has been used as you can see from the discolouration of the exhaust system but it remains spotless inside and out.

Jaguar MK V Drophead Coupe

The Jaguar MK V is a fascinating part of Jaguar history. Not because it was wildly popular, nor because of its performance but because it marked a turning point for the company. The styling of the MK V is distinctly pre-war and evocative of the SS cars which came before it. The engine too was somewhat outdated using the straight six pushrod engine based on a Standard engine which they had used before the war. What the MK V did have was an innovative suspension and chassis design nearly identical to the XK120 which provided class-leading handling and ride comfort.

The MK V had a relatively short production run from 1948 to 1951 when it was replaced with the MK VII saloon. The MK VII was a leap forward featuring more modern styling and the by-now famous XK engine. The chassis design remained essentially the same resulting in a car which truly embodied the Jaguar slogan ‘Grace, Space and Pace’.

The MK V pictured here is with us to investigate a clonking noise from the rear. This was traced to the splines on one of the half shafts. Although the MK V uses a Salisbury axle like most XKs the half shafts are unique to this model. As such we are having a new half shaft custom made.

Jaguar XK140 restoration

One of the defining features of the XK120 and XK140 dropheads and fixedheads is their stunning walnut-veneered dashboards and door cappings. These give the cars a real feeling of class and quality. If these items are not done well though it can really let a restoration down. Poorly fitted panels with big gaps or switches which do not line up well in the holes really catch the eye in a negative way. You can spend a fortune on the best veneering but if the wood does not fit properly then the finished product will never look right.

To ensure every aspect of our cars looks top notch we trial fit and alter the woodwork before veneering. This allows us to get the best possible fit for all parts and avoids the risk of damaging the veneer trying to alter parts later on. We will also build up the dashboard with all the switches and bezels at this point to ensure everything fits properly.

As you can see we take every opportunity to ensure our restorations are top class. If you are interested in having a car restored or require assistance with a home restoration please do get in touch to discuss how we might help.