SS100s, XKs and E-Types – workshop update

Both the workshop and storage floor are full to the brim with plenty for work to keep us busy. We have been quite overwhelmed by the support and interest we have received this year since moving to our new workshop. It has not been an easy journey, but it has been hugely rewarding and the finished result is nothing short of wonderful. It is great to have such a fantastic environment to work in. We are now booking a good way ahead so if you are planning to have work completed before the spring, please do get in touch so we can schedule you in.

We are now looking ahead to the Motoring Literary and Art Festival on the 2nd and 3rd of December. The event is being held in a heated hall inside The Wing building at Silverstone Motor Circuit. The event is devoted to motoring books, magazines, art and automobilia. The fantastic programme of speakers and discussion panels includes the great and the good from across the motoring and motorsport world so it is an event not to be missed. We will have a stand there with some interesting cars on display and are very much looking forward to immersing ourselves in the event. Tickets are available from the Motoring Literary and Art Festival website.

In this week's update, we feature every Jaguar sports car from the SS100, through the XK range all the way to the E-Type. We look at an XK140 which is used as a regular driver in London, a couple of restorations, SU carburettor rebuilds, a pair of SS100s and much more.

Jaguar E-Type recommissioning

Pictured here is a very early Jaguar E-Type. These are known as OBL or ‘outside bonnet lock’ E-Types due to the distinctive locks on the outside of the bonnet. Later Series 1 E-Types had bonnet locks inside the car. Other distinguishing features of the very early E-Types were their 3.8-litre engine, Moss gearbox and flat floor. The flat floor was changed in the later 3.8 litre production to a dished floor making the cars more comfortable to drive. The interior of these early cars also stands out with an aluminium dashboard and centre console along with bucket seats. A final distinguishing feature of these very early carburettors is that the inlet manifold has three pivot points for the throttle linkage like an XK150. On the later 3.8 E-Types, this changed to just two pivot points. There are no doubt many other distinguishing features, large and small that we have missed. If you think we have missed anything off this list please do let us know.

This particular car joined us to be recommissioned for the road after some time in storage. It is absolutely exquisite throughout. We think the Gunmetal Grey paint with Red interior is amongst the best finishes you could have on an E-Type. What a stunner!

High Octane XK140

This Jaguar XK140 fixedhead belongs to our friend Robert Coucher. Robert grew up with classic cars and has owned all sorts from a Lancia Aurelia B20GT to a Porsche 356C. He is the founding editor of Octane magazine and is currently Octane's International Editor. Robert is well known for regularly using his XK140 for transport around London. For those interested, there is a great video on YouTube by Porter Press interviewing Robert as he drives Philip Porter around London in the XK140. Not only is this a stylish way to travel but an XK140 also has the benefit of being ULEZ exempt as it is over forty years old. This of course makes perfect sense as despite relatively high tail emissions classic cars have a very low impact on the environment. The carbon produced to build them happened decades ago and the longer you can keep a car on the road the better value you are getting from that carbon investment.

Given how the car is used it is clearly vital that it is in tip-top mechanical condition. It is a pleasure to be entrusted with such a car and to have the opportunity to ensure it continues to provide reliable transportation.

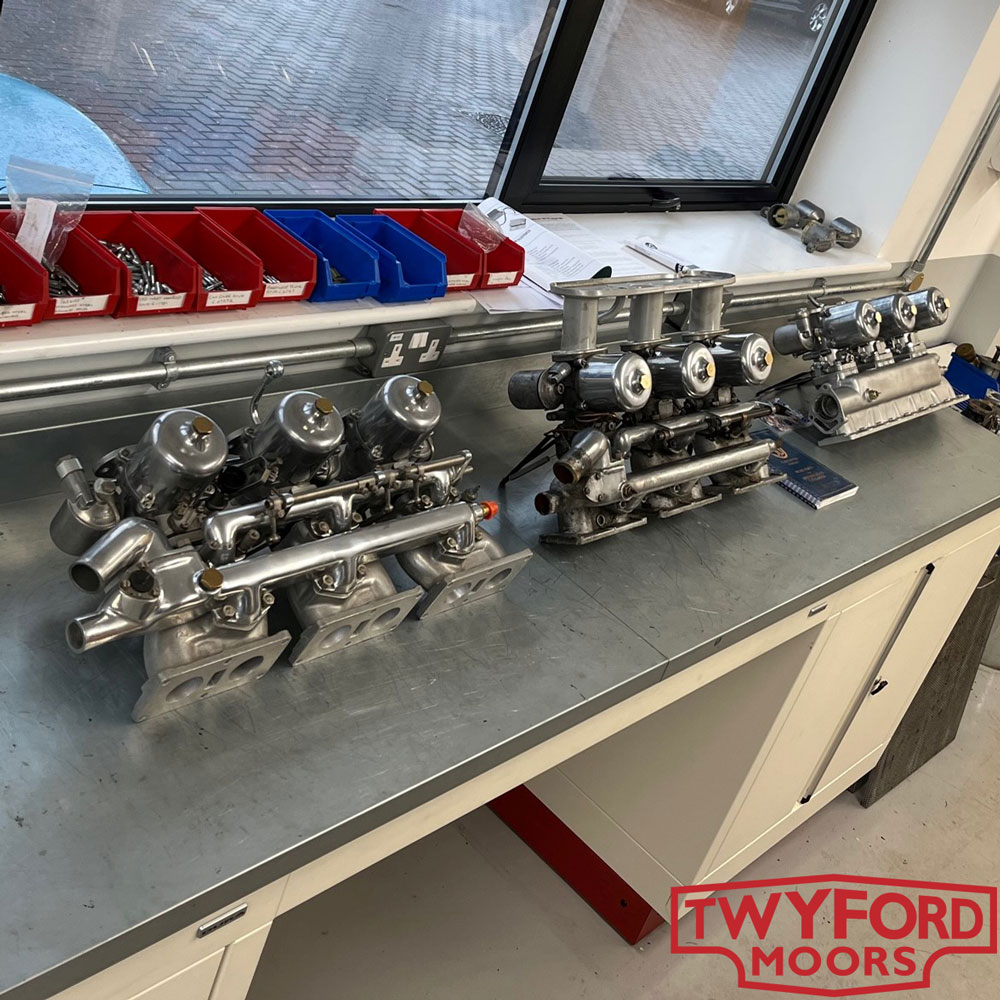

Triple SU carburettors

We have been undertaking a lot of carburettor rebuilds in recent months. We undertake this work predominantly for cars we have in the workshop but increasingly for those who choose to remove their carburettors themselves and then send them to us. Our new workshop, top-of-the-range cleaning machines and wealth of experience mean we can offer this kind of work to a wider audience than before. If your carburettors are in need of attention, whether they are from an Austin, MG or Jaguar please do get in touch.

We believe that a major reason we are undertaking so many carburettor rebuilds this that the higher ethanol content of modern fuels is starting to take its toll on old seals and components. When we rebuild a set of carburettors we use ethanol-resistant components wherever available. We also believe that our wet blast cleaning process also helps to protect aluminium components from the corrosive effects of ethanol though given we are in the relatively early days of these higher ethanol fuels only time will tell for sure.

For geek points who can correctly identify what cars these three triple carburettor inlet manifolds are for? I will give you a clue that they are all for Jaguars.

Jaguar E-Type restoration

We are just getting started on a full nut and bolt restoration of this Jaguar E-Type. It is a 3.8 litre Series 1 though not one of the very early OBL cars. We adore the E-Type Coupe shape, and it is an honour to be trusted with this magnificent car. This is a complete car in fairly good condition but when it was previously restored it was not done to the standards we expect today. We are therefore carefully stripping it down and cataloguing the parts before they are refurbished. The body will be taken back to bare metal and inspected before any necessary repair work is undertaken.

The owner of this car has always wanted an E-Type Coupe and has a very clear idea of the specifications required. We have been looking for some time for a suitable project car and although this one is arguably a little too good to be restored there are a number of advantages to buying the best possible restoration project you can. Having a largely complete car is a huge advantage when undertaking a restoration and can be a significant cost saving down the line. It is also nice to built a car with as many of its original parts as possible.

Jaguar XK120 negative earth conversion

Originally the Jaguar XK120, XK140, XK150 and early E-Types were built with positive earth electrical systems. This was the standard approach of car manufacturers at the time and was largely done as it reduced the risk of corrosion. This was all before the use of solid-state diodes became commonplace in the automotive industry. Diodes by their very function and design will only allow current to flow in one direction and therefore necessitated that cars started being built with negative earth electrical systems. The 4.2 litre E-Types are an example of this where Jaguar used an alternator instead of a dynamo to charge the battery requiring them to be built with negative earth. These days there are many workarounds to keep your car positive earth if you so wish but generally speaking the advantages of a negative earth system are overwhelming.

This XK120 came in to be converted from positive to negative earth and have a dynator (an alternator in the casing of a dynamo so it looks original) fitted. At the same time, the owner asked us to convert the car from its pair of 6v batteries to a single 12v battery which is a much more reliable arrangement.

Jaguar XK140 windscreen fitting

This shot is of the ongoing Jaguar XK140 drophead coupe restoration which we have shared in the past. Much progress has been made and the car is approaching being ready for start-up. We will get the car running and tested mechanically before it goes to be trimmed. That way if we have any issues which require rectification work we do not risk marking or damaging beautiful new trim.

Pictured here the windscreen is being fitted. This is a tricky process, especially with the split-screen cars, and is a task which requires both patience and experience. We often receive phone calls from XK owners who have had modern windscreen fitters attempt this task and fail, or worse break the glass. Unfortunately, most modern glass fitters simply are not equipped to fit an XK windscreen any more than we are set up to fit the screen into a modern F-Pace. It is noteworthy when undertaking a restoration that we always have the windows made to measure to ensure they are just the right size for the car. No two XKs are quite the same and a one size fits all approach just doesn’t cut it. If you wish to discuss classic Jaguar windscreen replacement, please do get in touch.

Jaguar XK150 clutch replacement

Pictured here in the foreground is the engine and gearbox having just been lifted out on the XK150 in the background. The car in question has come in with a clutch fault and the only way to properly assess this on this particular car is by removing the engine and gearbox together. It is possible in some cases to remove the gearbox from an XK through the car but it is often not advisable, practical or cost effective. With the engine out the customer is taking the opportunity to have both the engine bay and engine cleaned. We will also repaint the engine block and sump before it is refitted to the car.

Once the gearbox, bell housing and clutch had been removed it was clear that the fault was being caused by the spigot bearing. This had worked its way out and was pressing against the gearbox input shaft. It appears that this must have been an issue in the past as someone has tried to peen over the edge of the hole to hold the bearing in place. The offending item was removed and replaced along with other necessary repairs ready for the engine and gearbox to be refitted.

Jaguar XK150 headlights

A frequent request we have from customers is to improve their headlights. There are a lot of products out on the market which claim to improve the lighting performance of classics but our experience of these has been mixed. We have in particular seen a lot of issues with LED bulbs fitted to classic cars. We are always trying new things and sincerely hope to find LEDs which work well and reliably but what we have experienced is not yet up to scratch.

So, what can be done to improve the lights on XKs and E-Types? First and most important but often overlooked is the condition of the wiring, the switches and the fuse board. There are plenty of places where extra resistance can be introduced into the system making your lights dimmer than they would otherwise be. Next, check that your charging system is giving sufficient output. Once these two things are sorted you should see that your lights are brighter. After this check the light units themselves. Are they dirty or corroded inside? Are they aimed correctly? Finally, if everything else is in good order you can think about changing the bulbs. We would recommend upgrading to a pair of good-quality halogen bulbs rather than LEDs. Unfortunately, this is not appropriate for XK120s with original headlights. For XK120s or anyone looking for even more light beyond what we have already suggested we recommend fitting a good pair of spotlights with halogen bulbs.

Jaguar XK150 retrim

We usually focus on mechanical work in these posts but here we have the opportunity to look at the softer side of XKs. This Cotswold Blue XK150 is in with us for a full retrim of the interior and hood. The first stage, as you can see here, is to strip out the existing interior and strip off the hood. With the mohair cover off the inner padding is exposed over the frame here. This is part of what makes an XK drophead such a nice and refined car to be in. Having a properly padded hood like this was a rare thing in 1950s sports cars and really makes a significant difference.

Once the hood was stripped we found some of the wood had gone rotten. This wood will be removed and replaced. This has to be carefully shaped by hand to fit the car perfectly.

We will share a photo once the car has been trimmed and is looking perfect once more. If your classic Jaguar requires some cosmetic work, however big or small, from engine bay cleaning to retrims, please get in touch.

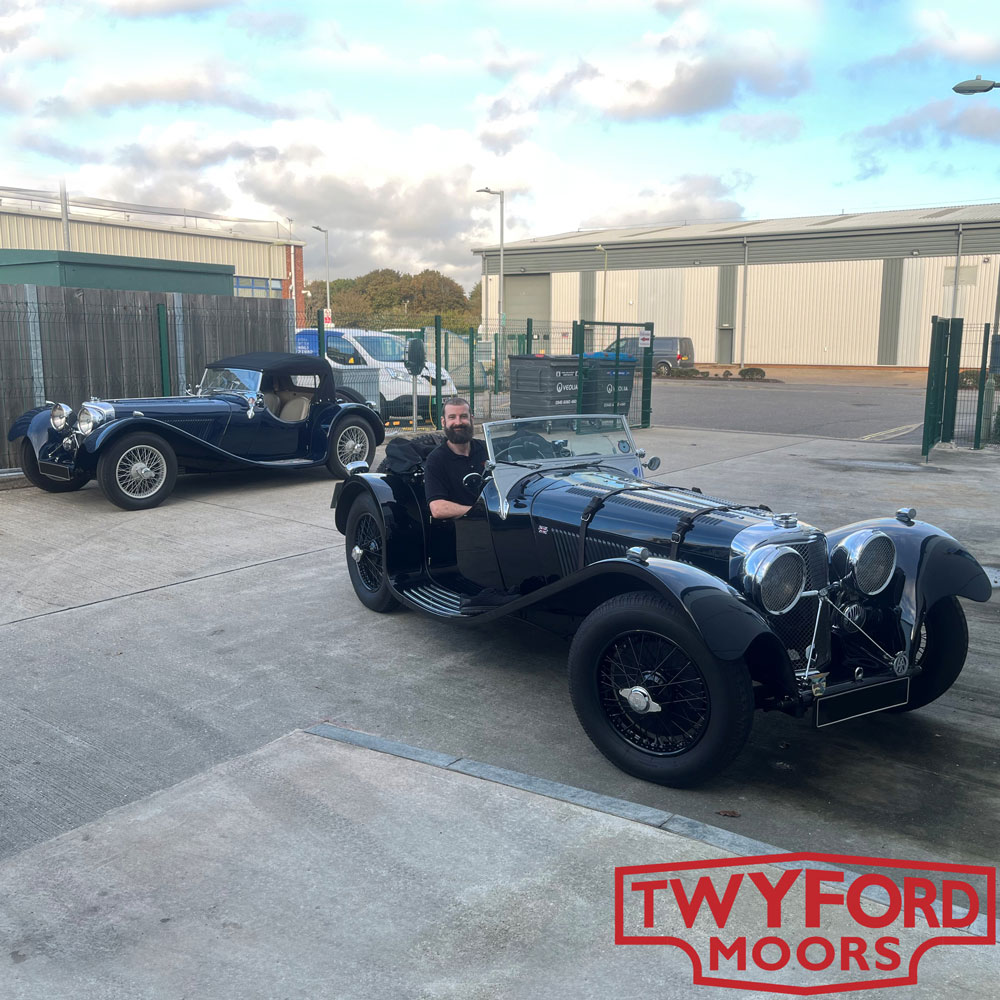

Seeing double

SS100s are exceptionally rare cars so we couldn’t pass up the opportunity to get a photograph of two of them in our yard. In fact, we have gained a bit of a reputation for working on SS cars and see quite a few come through the workshop. You can see from the photo how pleased our resident SS engineer is to have a pair of these beautiful cars in at the same time.

For those of you who are not familiar with Jaguars early history SS Cars Ltd was what the company was called before World War 2. The SS name was derived from Sir William Lyons earlier company Swallow Side Car. The SS100 was officially named the SS Jaguar 100 which is where the Jaguar brand first came from. Manufactured from 1936 until 1939 the SS100s production run was cut short by the war and only 314 cars were produced including one fixedhead coupe. The SS100 was named for its theoretical top speed of 100 mph, a naming convention that continued with Jaguars post-war sportscars like the XK120. The performance of these cars is quite breathtaking by pre-war standards and it is little wonder that they had so much success in motorsport.

Jaguar XK150 suspension rebuild

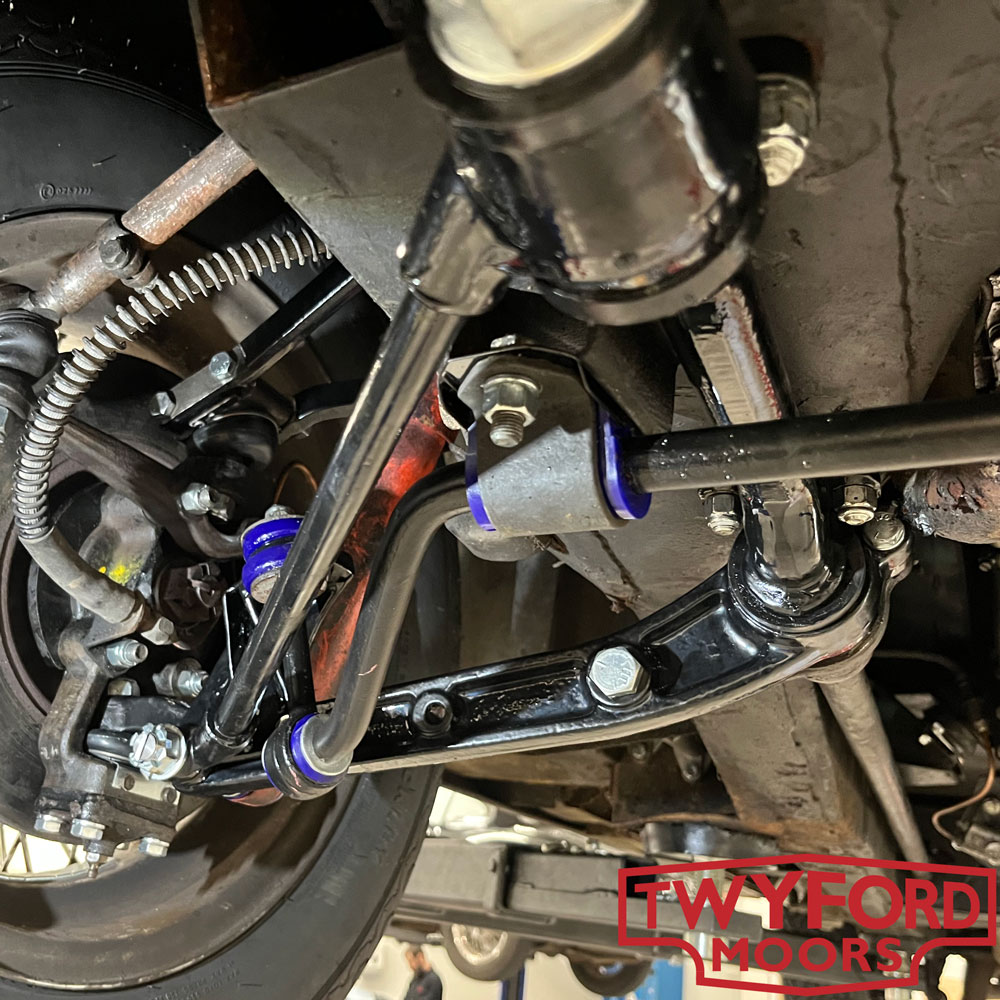

One of the defining features of the Jaguar XKs in the 1950s was their ride and handling. For their time their suspension set-up was groundbreakingly advanced for a road car, offering an almost unheard-of combination of comfort and performance. The front suspension utilised a torsion bar, wishbone and a telescopic shock absorber along with an antiroll bar to provide its wonderful driving experience. Along with all these components come a lot of bushes. With time and use these suspension bushes wear and perish, gradually compromising the suspension performance and in extreme cases making the car unsafe. In our experience, it is very common to see XKs with well-worn bushes which should have been changed many years ago.

Pictured here is the off-side front suspension of an XK150 having just been rebuilt. All the suspension components have been powder-coated to provide long-lasting protection. The suspension bushes have been replaced with polyurethane bushes which are longer lasting and provide superior performance to the original. With all this done the car will drive better than ever and the bushes will last many more decades before needing replacing.